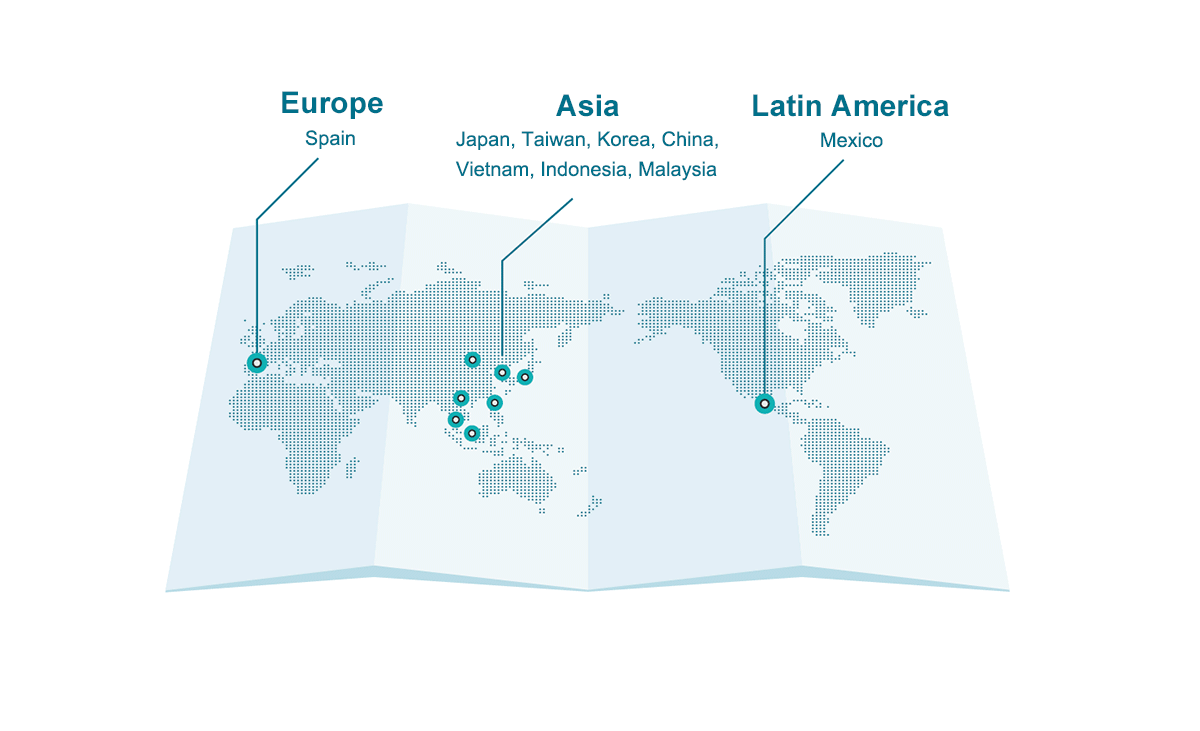

A Global Supply Chain Tailored to Enhancing Productivity

Chori has developed strong partnerships with major synthetic fiber manufacturers in Asia and other parts of the world and boasts a lineup that covers an extensive range of genres, from standard yarns to differentiated functional yarns. Utilizing our global network of local subsidiaries around the world, we ensure strict quality control through close cooperation between our manufacturers and the managers of our production sites. By combining and fully capitalizing on the sophisticated technologies of partner manufacturers, we produce functional yarns that differentiate us from our competitors.

- ECO BLUE™ at a Glance

- Network

ECO BLUE™ Initiatives

Inquiries

about ECO BLUE™